Working in the thread rolling industry for over 60 years, CJWinter has seen its fair share of thread rolling problems of all types.

Blank diameter, material type, and rate of penetration all play major roles in the performance of your thread rolling solution. Over the years, we identified the most common thread rolling issues and developed a series of solutions to address any challenge.

Of all the thread rolling problems we see on a regular basis, the following five represent the most common issues — and our recommended solutions to address them.

1. Slivers / Flakes

The appearance of slivers or flakes within threads can indicate a number of potentially problematic causes. First, check to see if rolls are mismatched, overfilled, or of the incorrect diameter. It’s possible that rolls need to be resynchronized or the blank diameter needs to be reduced to correct the problem.

Second, check to see if the center of the rolls is in parallel with the center line of the work; if not, make the necessary adjustments to ensure proper alignment. Thread flakes can be caused by a rough finish on a blank, requiring the tooling to be reground, or by a feed rate that is too slow, in which case the rate of penetration should be increased. Finally, it’s important to consider if the material is adaptable to cold-working. If it is not, a new material should be employed in its place.

2. Drunken Threads

Thread rolls with drunken threads have an erratic pitch, creating irregularities in revolution. Unmatched rolls and misalignment may be the culprits; check to see if rolls need to be resynchronized or the slides should be better aligned.

If any rolls are inaccurate, replace them with the appropriate roll. It is also possible that threads are bending during the rolling process; if this is affecting your process, provide additional part support during rolling or slow down the penetration rate to solve the problem.

3. Wrong Pitch or Lead

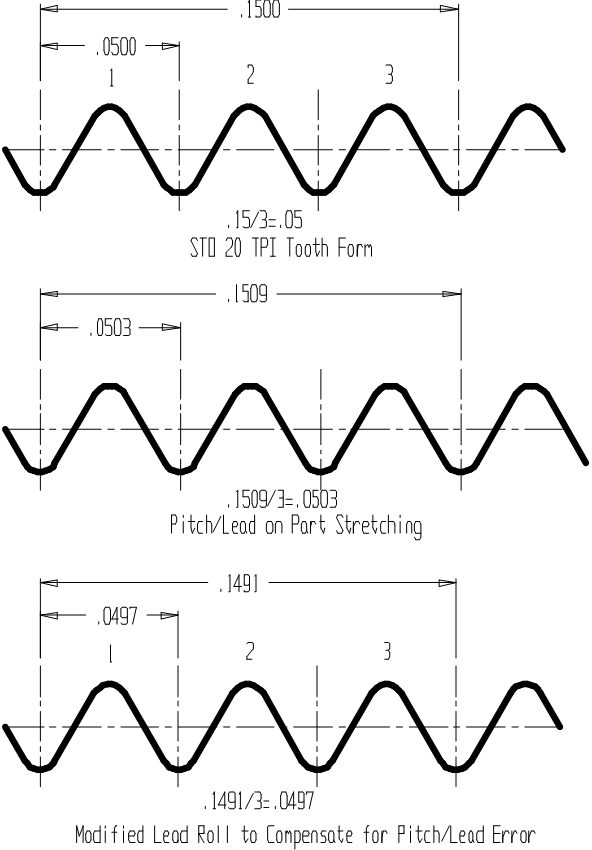

To address this problem, start by measuring as many full threads as possible using a comparator. This total measurement is then divided by the number of threads measured, resulting in the accurate pitch. In the event that the pitch has increased, resulting in a gauging problem, use modified lead (ML) rolls.

For best results, send sample rolled parts to your manufacturer so that they can confirm the problem and then design rolls that will correct the error and produce properly gauged parts.

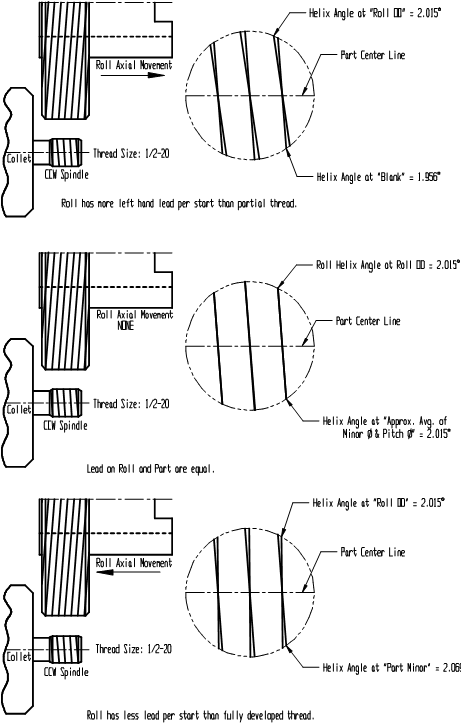

4. Mismatched Helix Angle

When a roll comes into contact with the blank, it can result in “screw jacking;” if the attachments or roll get pulled into the collet as a result of being kept on the part for too long, it causes mismatched helix angles. To address this problem, optimize your rolling time.

The longer the roll remains in contact with the part, the more likely problems will occur and negatively affect the overall quality. Instead, aim to insert and withdraw the roll as quickly as possible, allowing the thread to form properly but removing it right away once completed. This should result in fully formed, accurate threads.

5. Poor Finish

When thread rolling does not produce the desired finish, a number of factors may be to blame. First, check to make sure that the blank diameter is the correct size to ensure that rolls are not being overfilled. If the rolls are not synchronized, adjust them to ensure smooth operation.

In some cases, material can accumulate in threads from multiple uses; if this is negatively affecting the rolls and the material cannot be removed, the rolls need to be replaced. Contamination from nearby jobs can also affect thread rolling; if chips are coming in from a nearby operation, ensure that a stream of clean oil is reaching the rolling position to keep the job clear. Finally, ensure that the material being used can be cold-worked. If not, it should be replaced with a more appropriate material.

Don’t see your thread rolling issue above? If you’re struggling with a thread rolling problem and searching for a solution, visit our CJWinter troubleshooting page for recommendations related to scuffed crests, tapered threads, split threads, and more.

Lib Pietrantoni

Lib has been with the Brinkman International Group, Inc. for the last 30 years. Currently, the Director of Global Sales, Lib has held numerous positions in Engineering, Operations, Sales, and Product Management with CJWinter and its manufacturing divisions. Lib is a member and has served on governing boards for the Society of Automotive Engineers, The American Society of Mechanical Engineers, and the Precision Machine Products Association.