CJWinter manufactures the premier line of cylindrical rolls & machine dies.

We now manufacture both Helical and Annular machine dies in various styles for your thread rolling machine, including Through-Feed, Double-Taper, Speed-Up, Plunge, and Slow-Up.

CJWinter also offers machine dies for Reed overhung die holders and double support die holders for both straight threads and taper pipe threads.

Die Materials | |

|---|---|

D2 | Moderate toughness and intermediate wear resistance. Supplied on dies for machine screw threads. |

DC53 | General-purpose cold work die offering twice the toughness of D2 with superior wear resistance and higher fatigue strength. |

M2 | High-speed steel with excellent toughness and wear resistance. Optimal for cold work dies. |

M42 | Super high-speed tool steel designed for machining high-strength and pre-hardened steels and nonferrous alloys. Ideal for aerospace and oil and gas industries. |

Optional | Other materials available upon request. Contact us for details. |

Edge Finish | |

|---|---|

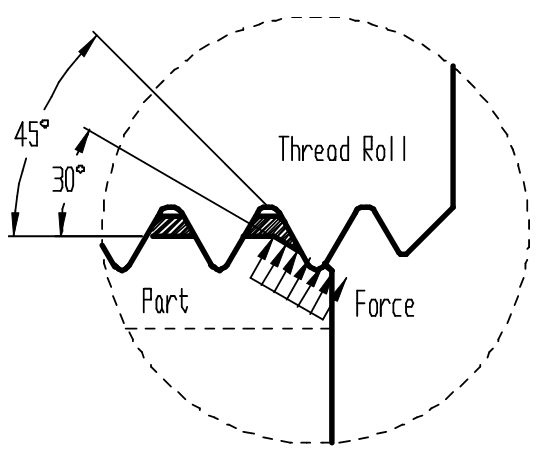

Standard | 30°, 45°, or 60° Chamfer Angles |

Custom | R3 Radius Root Chamfer or Custom Chamfer Angles |

When rolling, the recommended angle on each side of the blank diameter is 30° from the axis of the part.

A 30° chamfer will give an approximate 45°angle after rolling. For harder materials, a lower chamfer angle (25° to 28°) is preferred so thread roll life is not compromised.

To order a special chamfer or edge finish, please specify the chamfer angle and length.

Cylindrical Rolls for Reed

A22 and A23 thread rolling machines

Manufacturer | Machine Model | Spindle Diameter | Max. Die O.D. | Max. Die Width |

|---|---|---|---|---|

Escofier | H12 | 54mm | 170mm | 130mm |

H30 | 69.85mm | 220mm | 260mm | |

PEE WEE | PEE WEE P5 | 40mm | 120mm | 38mm |

PEE WEE P12 | 54mm | 195mm | 130mm | |

PEE WEE P15 | 69.85mm | 200mm | 160mm | |

PEE WEE P20 | 54mm | 195mm | 160mm | |

PEE WEE P24 | 69.85mm | 195mm | 150mm | |

PEE WEE P25 | 69.85mm | 195mm | 150mm | |

Izpe | RSC300 | 54mm | 160mm | 120mm |

RSC300H | 54mm | 220mm | 200mm | |

Kinefac | MC-5-F | 1½” | 4″ | 2½” |

MC-5-F | 2″ | 4 3/8″ | 2½” or 3½” | |

MC-25-F | 2″ | 6″ | 4½” | |

MC-50 | 3″ | 9½” | 7″ | |

Nissei | FA-3S | 26.05mm | 60mm | 30mm |

FA-5S | 40mm | 100mm | 50mm | |

FA-10 | 54mm | 140mm | 80mm | |

FA-16 | 54mm | 160mm | 180mm | |

ORT Italia | 3RP8 | 28mm | 80mm | 150mm |

3RP15 | 40mm | 175mm | 80mm | |

18B | 54mm | 185mm | 150mm | |

3RP42 | 69.85mm | 215mm | 150mm | |

RP50 | 80mm | 215mm | 150mm | |

Reed | B112 | 2 1/8″ | 6″ | 3 1/8″ |

B210 | 2 1/8″ | 5½” | 3 1/8″ | |

B220 | 2 1/8″ or 2¾” | 7 7/8″ | 5 15/16″ | |

B230 | 3 1/8″ | 11¾” | 11¾” | |

B250 | 3 5/16″ or 3 15/16″ | 11¾” | 9 7/8″ | |

REGG ROLLING | R40HD | 40/54 mm | 180 mm | 100 mm |

R125HD | 54 mm | 190 mm | 120 mm | |

R180HD | 69,85 mm

| 235 mm

| 150 mm

| |

2R125HD

| 54 mm

| 190 mm

| 120 mm

| |

2R180HD

| 69,85 mm | 235 mm | 150 mm | |

3R40HD | 22/25 mm | 75 mm | 40 mm | |

3R125HD | 40 mm | 80 mm | 60 mm | |

3R180HD | 54 mm | 170 mm | 90 mm | |

3R300HD | 69,85 mm | 210 mm | 120 mm | |

Seny | D25E | 40mm | 125mm | 50.8mm |

D30 | 40mm | 100mm | 60.325mm | |

D40 | 40mm | 120mm | 70mm | |

D44H | 40mm | 120mm | 80mm | |

D50H | 54mm | 170mm | 101.6mm | |

D75B | 54mm | 170mm | 158.75mm | |

Steinle | NO 1 | 2 ¾” | 5 ¼” | 3″ |

Tesker | 175 | 1 ¼” | 4 ½” | 2 ½” |

200 | Various | 5″ | 3 ¼” | |

215 | 1 ½” | 6″ | 4 ½” | |

320 | Various | 8″ | 5 ½” | |

425 | 3″ | 8″ | 8″ | |

Tsugami | 5D | 54mm | 150mm | 60mm |

T-ROL6 (A5D) | 54mm | 149mm | 60mm | |

T-ROL15 (15D) | 54mm | 180mm | 150mm | |

T-ROL20 (20D) | 70mm | 200mm | 180mm | |

T-ROL25 (25D) | 85mm | 210mm | 300mm |

CJWinter has proven that speedy delivery, flawless quality and competitive prices can all be delivered simultaneously for our machine dies.

Our team of dedicated engineers focuses on solving every customer’s thread rolling and machine die challenges. Our specialty is providing superior products in the industry’s shortest lead time.

From CJWinter, you get:

- Half a century of leading-edge service to the machining industry

- Individual attention

- Superior service

- Flexibility

- Meticulous attention to detail

- Innovation and quality

- Intensive hands-on training and experience

We understand what you need, and are able to customize jobs to meet your exact specifications.