How Controlling Major Diameter Can Extend Thread Roll Life and Cut Your Costs

In precision manufacturing, even minor deviations can lead to significant issues. One critical factor often

A single cam can be used throughout the entire size range, and pitch diameter can be adjusted even while the machine is running.

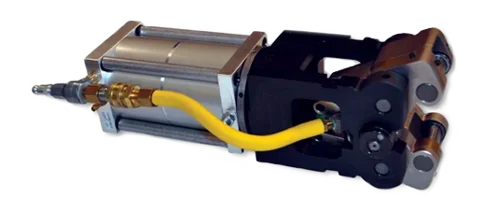

Pneumatic Attachments require one cubic foot per minute of compressed air at 80 PSI. Threads per inch, length of thread, and material to be rolled are factors to determining air pressure required. In most cases it will not exceed 80 PSI.

In precision manufacturing, even minor deviations can lead to significant issues. One critical factor often

Thread rolling is widely recognized for its ability to produce strong, reliable threads without removing

The United States uses ANSI’s American National Standard Pipe Thread Standards to regulate the formation